Comparing Different Extraction Methods of Sesame Oil

Abstract

Sesame seed has the most oil compounds (%50), but all of its oil not extracts due to being difficult of extraction. The target of this review article is comparing different extraction method of sesame oil. Sesame oil extraction methods categorizes in two groups; laboratory method and industrial method including, Hot water flotation, Ram Press, Ghani Process, pressing method, subcritical liquid method, soxhelet method, fractionation, and enzyme extraction. The amount of extracted oil and time are different in this method. Efficiencies of hot water floating, poly press, ram press, Ghani process, subcritical liquid, soxhelet, fractionation, and enzyme methods were %41, %70, variable, %26.47%, %34.23, %58.93 and %58.87 respectively.

Introduction

Sesame is one of the agriculture crops which are estimated belonging to over 4000 years ago. This product consumed in different food industries such as, alcoholic beverages, seasons and nuts), pharmaceutical and hygiene industries. Sesame seed contains % 50 oil.

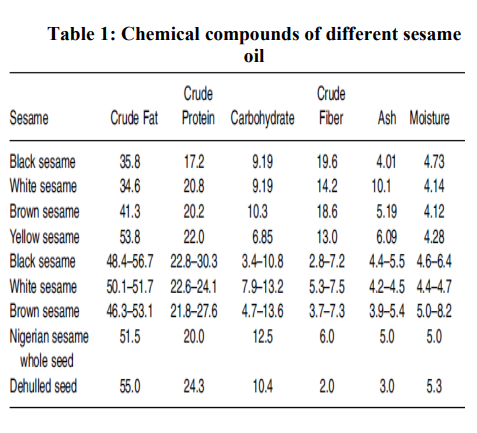

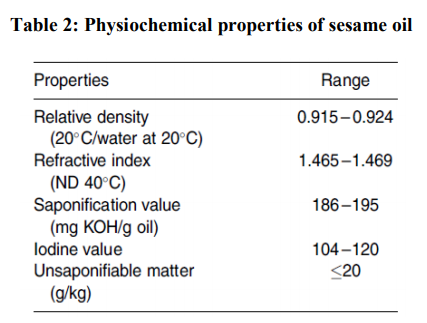

But due to difficulty in extraction, some parts of its oil are impossible to be extracted. Unlike high saturated degree, sesame oil is one of the stable oil. In recent decade, the amount of its production has grown (Hwang. 2005). The chemical compounds of sesame oil contain protein (%18-25), carbohydrate (%13.5), and ash (% 5) (Borchani and et al. 2010). Table 1 shows different compounds in sesame oil at which the amount of its oil was more than other oil sources (soybean, canola, sunflower and cotton) which is %28-59(table 1).

Physiochemical properties of sesame oil presented in table 2

Sesame oil belongs to oleic-linoleic acid. The amount of fatty acids has been depicted in table 3. The amount of oleic and linoleic acid are the same

Result and discussion

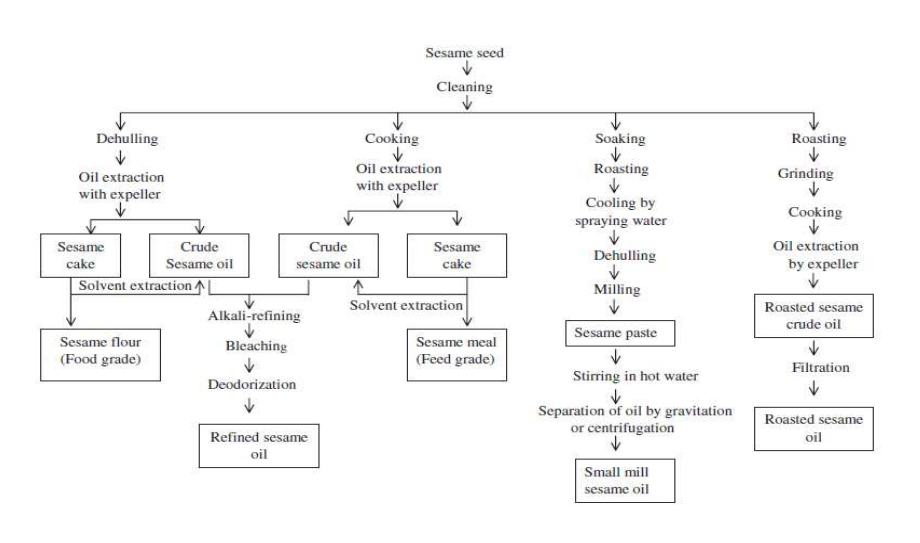

Processing

Processing is collection of measurements in order to provide foodstuff to be ready for consumption which depends on two parameters; 1) removing of seed husk, 2) fried seed. All processing methods including refining of sesame oil obtained from crude seeds (with/without husk), fried oil resulted from fried sesame, sesame oil produced from nonhusk fried sesame seeds.

Fig.1: Diagram of different sesame oil processing

Peeling

Husk peeling is essential as a result of the presence oxalic acid and non-digestible fiber. This process leads to oxalate be removed, then initial stages for providing sweet sesame with bright color, low fiber and protein provides

Oil extraction

Oil extraction using laboratory method Modern methods using normal hexane and enzyme extraction. Sesame oil extraction by subcritical CO2 has reported as well.

Industrial method

Hot water floating method

Grounded sesame seeds forms to a paste, heats to 80°C-90°C for 15min, then shakes while boiling for 15min, after cooling, upper layer removes and dried by heating, efficiency of this method is %41

Poly press

Sesame seeds smashed through a plate with mesh 2mm. In this method as much as fine seeds consumed, obtained oil has better quality. Extraction is performed through adding water (%11-13 w/w), the resulted paste dried at 70°C.

Ram press

In this method, there is no need to initial grounding,however beginning on metal sheets. Kapo press cause to produce clear oil with %57.7 efficiency.

Ghani process

12kg of seeds grounds in mill with 0.5 L water, after 30 min oil releases and temperature increases to 55-60°C causes to excretion of 5 L oil

Demanding Press machinery

This is common method in which Sesame oil can extract under low temperature condition with no touch to chemical solvents or high temperatures. After extraction, neutralization and cleansing perform to enhance oil quality .

Figure 2: Extraction of Sesame seed using press machine

Subcritical Liquid

CO2 uses as solvent along with ethanol, under 20MPa, 35°C, 5.2gCO2/min, and the process lasts 210min and its efficiency %26.47.

Soxhelet extraction

This process continues up to the level of removing oil from seeds in presence of petroleum ether and ethanol as solvent for 8hr.

Fractionation extraction

This method performs through ethyl ether, ethanol and water.

Enzyme extraction

Sesame oil extraction can be improved by adding enzyme to water solution. Sesame oil can extract by demanding different enzymes like papain, Tripsin and cellulase. Enzyme extraction in neutral condition i.e. at 50° C, 3hr, 80 rpm, enzyme amount were 6000,400 and 250U/g is %58.87.

Total conclusion

The most extracted oil was related to poly press method with %70 efficiency.