Peanut Oil Production Line

Fragrant Peanut Oil Production Line

The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved “no chemical production”. The fragrant peanut oil obtained by pressing process maintains the natural ingredients and aroma of peanut oil, and it is rich in antioxidant vitamin E and has a long shelf life, so there is no need to add chemical antioxidants for storage; it is a pure natural oil products that are produced by combination of modern and traditional technology. With the improvement of living standards, the fragrant peanut oil is deeply loved by consumers for its unique pure fragrant flavor and have a broad market prospect. And the production line can be customer-made according to material variety, factory location, and labor resource.

Peanut Oil Production Process and Operating Points

In order to ensure the nutrition, flavor, and safety of fragrant peanut oil and reduce the cost, we adopt a physical squeezed method in the peanut oil production line. And the features of the pressing line are: (1) Extraction adopts pure physical pressing method to completely avoids the contact of raw materials and chemical solvents throughout the entire production process; (2) To abolish the unfavorable refining process which affects the quality of finished oil, such as solvent leaching, alkali refining and deodorization, so as to ensure the natural nutrients in the refined oil. (3) The refined oil is stored in an underground storage and the cooling water coil technology is used to ensure long-term storage.

1. Production Processes

1.1 Raw Material

The raw material which is used to produce fragrant peanut oil is fresh, full-grained, undamaged, mildew-free, free of insects and has not undergone an aging period. Raw materials would be cleaned by removing immature, damaged, and moldy grains during the cleaning process.

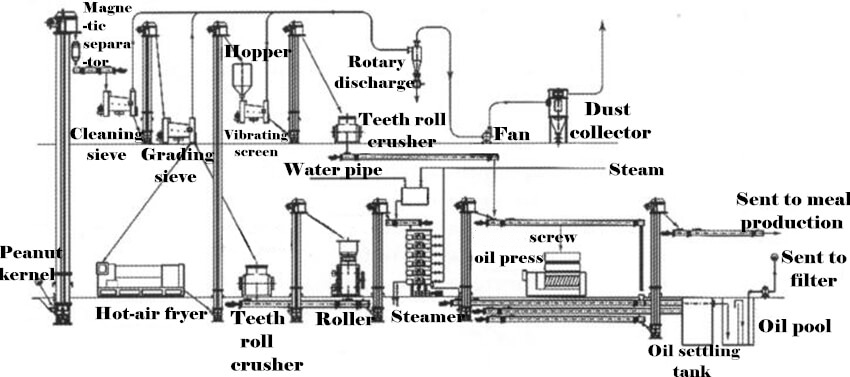

1.2 Process Flow of Peanut Oil Production Line

1.3 Process Parameters and Procedures

Peanuts are cleaned and shelled, medium-sized peanuts are screened (about 25% of the treated amount), and the rest are large- and small-sized peanuts (about 75% of the treated amount). The large-sized and small-sized peanuts are broken, rolled and steamed. The medium-sized peanuts are crushed and cleaned by red skin eliminator, then being baked. Finally, the three sized materials are mixed and then pressed in the press to obtain the crude oil. After pressing, the oil is settled and filtered to produce a fragrant peanut oil.

1.4 Operating Points

Stones, metals, etc. may damage mechanical equipment; moldy, insect-infested peanuts will seriously affect the quality of the oil. In order to reduce oil loss, improve oil yield, ensure high quality of oil, and prolong the service life of equipment, the cleaning process should be strictly controlled. Metals could be removed by magnetic separation, using magnets to remove magnetic impurities in raw materials. Other impurities like stones are removed by self-regulation vibrating sieve, using peanuts and impurities’ difference in the particle size and weight, with the help of peanuts and impurities in the relative movement of the screen surface.

- Equipment: Self-regulation vibrating sieve, magnetic separator

The magnetic separator has the horizontal and vertical type. The separator is made of stainless steel, and the raw peanut flows through the body and the magnet separator extracts contaminants.Self-regulation vibrating sieve is widely used for separating impurities of large, medium and little-sized in grain, the machine has many features like the simple structure, smooth operation, low noises and consumption, good cleaning results, etc.

1.5 Peanut Oil Storage

The appropriate condition for peanut oil storage is 8% moisture content and the temperature which does not exceed 20℃. Sealed storage can prevent the infection of pests and the influence of the outside temperature and humidity, which is conducive to maintaining a low temperature.

Peanut oil is stored at a temperature below 15℃ in a sealed container to prevent lipase hydrolysis and oxidation, and to avoid the increase in acid number and peroxide value. The average temperature of the ground below 4m is below 20℃, so the storage house is built underground.

Factors That Affects the Fragrance of Peanut Oil

The Effect of Peanut Raw Material Itself

The oilseed used to produce fragrant peanut oil requires full grain without aging period. Immature, broken, mildew and aged grains cannot be used to produce aromatic peanut oil: The acid value of oil produced by immature and aged grains is higher and the flavor is poor, while moldy and damaged grains are liable to be contaminated by aflatoxin. Therefore, in the production process, these oilseeds must be separated for the ordinary secondary oil processing alone.

The Effect of Baking Temperature

Hot-air roasting is a key process for the production of fragrant peanut oil. The flavor of peanut oil has a direct relationship with the baking temperature. The temperature is too low and the fragrance is lighter; the temperature is too high and the oil is prone to scorching. The baking temperature is generally controlled at 180℃~ 200℃. In order to prevent the gelatinization and spontaneous combustion of the oil, it should be cooled immediately after baking.

The Influence of Steaming

The steaming of embryo is another important step in the production of strong fragrant peanut oil. The level of oil content, flavor and color, and the content of phospholipids and pectin-soluble components in fragrant peanut oil are directly related to the steaming process. High-moisture steaming embryo technology should be adopted to adjust the moisture content of the oil in the steaming cooker to 12% to 13%; within the pressure range that the equipment can withstand, try to increase the pressure of indirect water vapor, generally controlled at 0.6MPa~MPa; and enterprises with conditions shall be encouraged to use hot water steam. In the process of steam cooking, it is necessary to make the phospholipids and peptic substances absorb water to combine with the protein, which is the key to guarantee the qualified test of the refined oil 280℃ heating and improve the transparency of refined oil.