Sunflower Oil Production Process Introduction

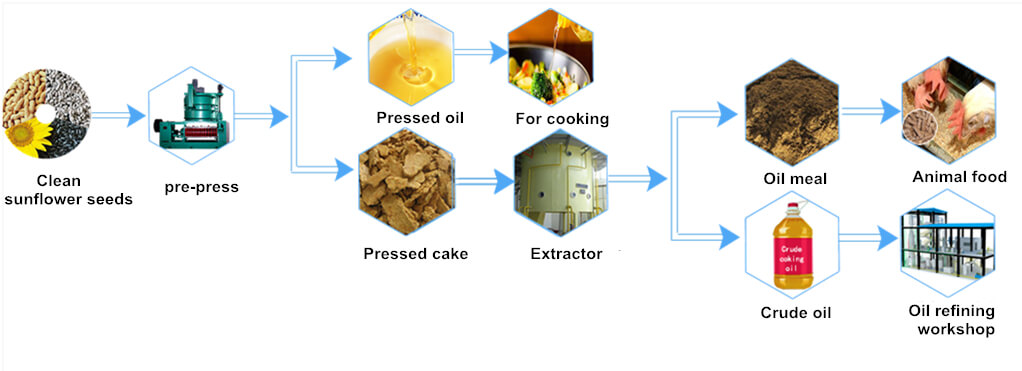

Sunflower oil is an excellent vegetable oil which is extracted from sunflower seeds that begin with sunflower seeds pre-treatment, pre-pressing, embryonic material leaching, wet meal desolventizing and crude sunflower oil refinery process. Sunflower seed oil is rich in linoleic acid, which helps reduce blood cholesterol levels in the body, and is beneficial to protect cardiovascular health. Besides the unsaturated fatty acids, sunflower oil also contains vitamins E, folic acid, iron, potassium, zinc and other essential nutrients.

Currently, the sunflower oil sold on the market is mostly produced by de-shelled pre-squeezing and leaching process. De-shelled pressing-leaching technology is the key point of sunflower oil production line which avoids the negative impact of over-refining, high temperature, and acid and alkali effects on oils, so that the nutrients in the oil can be well preserved. For example, the content of vitamin E in de-shelled squeezed sunflower oil is 75.5mg/100g. However, by squeezing-leaching seeds with shell, every 100g sunflower oil only contains 41.62mg vitamin E. What’s more, there is no contact with alkane in the process of the un-shelled pressing-leaching process, which avoids the formation of trans fatty acids.

Sunflower Oil Processing Steps

The processing characteristics of first-grade sunflower oil are: First of all, sunflower seeds are selected and cleaned to remove impurities, and then the seeds are de-husked and crushed. After that the embryo is flaked and steamed in the frying pan, the fried product is pre-squeezed out of the oil and the remaining oil is extracted by solvent leaching, then the crude oil is purified through precipitation and filtration. Finally, the oil is dissolved, degummed, decolorized, deacidified and deodorized into the refined oil. More specifically, the operation steps and equipment for processing sunflower oil are as follows:

Select the sunflower seeds with the oil content of 30~50%, and the seed material contains certain impurities (sediment, stones, iron filings, etc.) which should be removed by cleaning sieve and magnetic separator.

Equipment

Oil cleaning sieve, magnetic separator.

Oil cleaning sieve is mainly to remove the impurities in the seed material, and the magnetic separator can remove iron filings.

Process features

(1.) The machine is driven by a vibrating motor, and the size of the excitation force, vibration direction, and the inclination of the sieve body can be adjusted according to the characteristics of the oilseed, which cleans up the oil more thoroughly and cleanly;

(2.) Oilseed cleaning could reduce the wear of subsequent equipment and the dust in the workshop is reduced, too;

(3.) Smooth operation, good cleaning effect, and high production efficiency.

Features of Sunflower Oil Production Line

Characteristics of the oil pressing and extracting

- Compared with other oil extraction methods, the oil pre-pressing has the advantages of simple process, less supporting equipment, strong adaptability to oil varieties, flexible production, good oil quality, light color, and pure flavor.

- However, the cake has a high residual oil content after squeezing, resulting in high power consumption and easy loss of parts. This method can be used to extract oil from peanuts, rapeseeds, sunflower seeds and other seeds or nuts. At the same time, the pre-pressed cake is sent to the leaching workshop to further extract the residual oil in the cake to achieve a better oil-making effect.

Characteristics of the oil refining process

- For the refining part, we provide a full set of equipment for batch refining process, semi-continuous refining process, and full continuous refining process(more than 50 tons per day).

- Batch refining process has a daily capacity of 1~30 tons of sunflower oil. It has features of less investment, convenient operation and small footprint.

- Semi-continuous refining process has a daily capacity of 30~50 tons of seed oil. It can be used for different types of oil refining, and it has advantages of low power consumption, better refining rate than batch-type and traditional semi-continuous processes.

- Full continuous refining process has a production capacity of more than 50 tons per day. With characteristics of high refining yield and low consumption of auxiliary materials, full continuous refining process can meet the requirements of deep processing of products. The process requires continuous operation, which is suitable for larger scale production of the continuous production enterprises.