Why Refining Edible Oil?

Oil Refining is a progress of removing the impurities such as phospholipids, FFA, pigment, off-flavor in cruel oil before edible application. Oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining equipment. With the high degree of automation, the oil refining machinery can refine 20 kinds of edible oil, such as soybean oil, rape seeds oil, peanut oil, etc. in a small production line or in large oil plant.

Edible oil refinery caters to people need in pursuing quality life and exports from abroad. Why refine edible oil?

–The oil without refining will give out quite a lot smoke and make people uncomfortable. Refined oil is less smoke and preserves more authentic flavor.

–Refining mainly aims to purify edible oil by degumming and neutralizing and get high-quality edible oil.

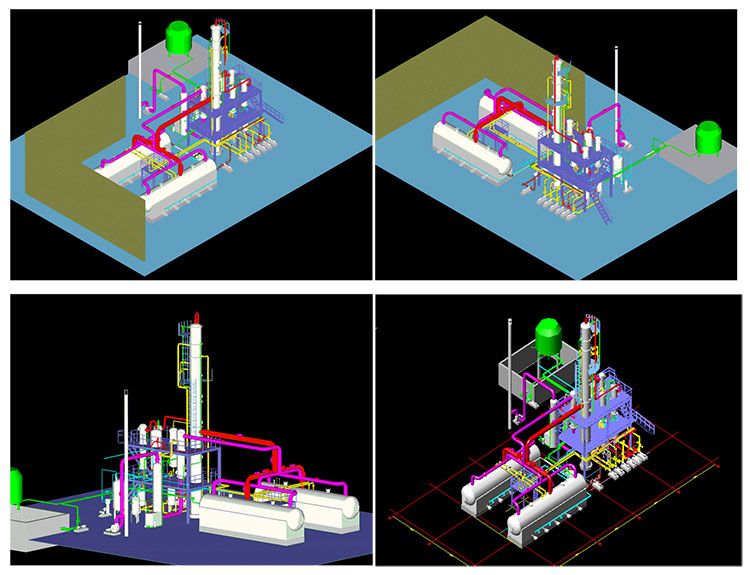

Oil Refinery Progress

Degumming

This progress adopts hydration by adding hot water to remove the agglomerated and deposited hydrosol and phosphatide because of their water affinity. The separated gum (after being dried) can be made into lecithin or added into cakes or meals in the extraction workshop. Hydration degumming process can improve oil edibility, storage and do well to downstream neutralization section.

Neutralizing

Oil containing fatty acid is mixed mechanically with a slight excess of alkali to react with fatty acids present to form soaps. The mixture is centrifuged to separate oil from soapstock. After washing with water, the water is separated from the oil in a second centrifuge.

Bleaching

Degummed and neutralized oil are pumped into this system and mixed with by the use of bleaching earth, a special soap, gum, and pigment attracting adsorbent. The mixture enters the Pre-filtration Dryer where the moisture in the oil and adsorbent is evaporated. Then the oil is pumped through an automatically closed filter to remove clay.

Deodorization

The oil contains the disagreeable flavor and odors that are naturally present or created during processing. All odoriferous matter is distilled off by injecting high-pressure steam through the vacuum system. Then the product achieves the national standard.